-40%

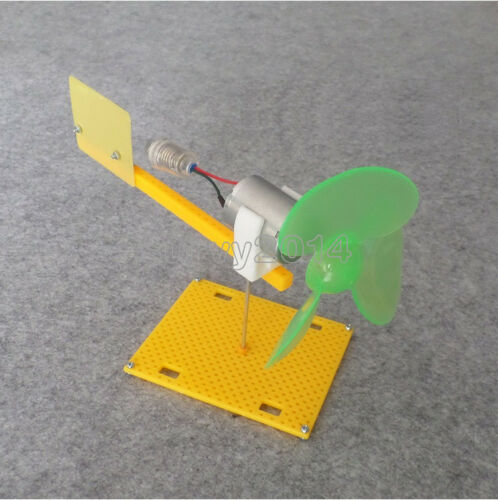

24V DC PMA Permanent Alternator Generator Gas motor / Hydro type PC1224DC PMA

$ 100.29

- Description

- Size Guide

Description

Permanent Magnet Alternators PMA Permanent wind turbine mills Magnet Alternator Permanent Magnet generator wind power PMG wind turbine wind turbinesThis Auction is for a #PC1224DC PMA -

Negative Ground.

GET YOUR BATTERIES CHARGED UP REAL FAST ON THOSE

GLOOMY WINTER DAYS

WITHOUT ANY SOLAR OR WIND

.

Keeps your batteries alive when using a power inverter during power outages.

#

PC1224DC -

is one of our best PMA's!

Below is a video of our dual-core model

Made for

24 volt DC battery charging only.

(DC model has build in DC

rectifier for EZ plug and play

)

2700 RPM MAX

LOW VOLT AND HIGH AMPS

2700 RPM MAXIMUM!

1075 RPM for >21 Volt battery charging. OPEN VOLTAGE

1650RPM for >27 Volt battery charging. OPEN VOLTAGE

2065 RPM for >29 Volt battery charging. OPEN VOLTAGE

2500 RPM for >38 Volt battery charging. OPEN VOLTAGE

2400 Watts peak power!

85 Amps @ 30 V

(At a

Maximum

Ohm Load)

ALL NEW Design

Includes 60mm pulley and cooling fan FREE!

Build an engine driven generator with our PC1212DC PMA (engine not included)

FOR BATTERY CHANGING - NOT FOR DIRECT HOOKUP TO POWER INVERTER.

HIGHLY EFFICIENT - USE LESS GAS OR DIESEL AND MAKE TWICE

THE ELECTRICITY USING A BATTERY AND POWER INVERTER!

BEATS TYPICAL 110/220-VAC GENERATORS BY 35% MORE EFFICIENCY.

Also highly recommended for engine, hydro and belt driven applications!

The wire size in these stators are extra large coils offering HIGH amperage. This wire is not fine enough for wind power applications

Includes cooling fan and pulley as standard equipment.

DO NOT REMOVE COOLING FAN! This model can get hot! VERY POWERFUL!!

Build a super battery charger out of any old lawn mower.

Specially made for belt drive use on engines or direct drive Hydro systems.

Lawn mower not Included.

THE WORLDS HIGHEST

AMPERAGE

PMA FOR IT'S SIZE AND CLASS RANGE !

Brand new, never used PMA!

Including the pole shoes and stator coil frame!

We make our own brand new

ROTOR POLE SHOES

AND STATOR CORES!!!

Make sure your rotor is brand NEW and

has also been re-balanced on a

dynamic

rotor balancing machine or your PMA

will NOT spin smoothly!!!

Our PMA's

are

NOT

re-built units

starting with 'Junk Yard' alternator parts.

Our

NEW

rotor poles are balanced to within .002 grams for SMOOOOOTH rotation!

PROUDLY MADE IN THE USA!

LOW COGGING / Power-Core PMA's have

amazing power and GREAT low speed start up!

Can be run Clock Wise (CW) or Counter Clock Wise (CCW) but when running CCW

the shaft requires a "Carter pin lock" to keep the pulley from coming off the shaft.

A must have item for off grid emergency power

for those days when there is no sun or wind!

Great for charging ;

DC rectifier built in! Puts out DC POWER!

2700 RPM MAXIMUM !!

By Hornet Power Systems

Use these powerful permanent magnet alternators

(PMA's) to make cheap electricity with wind turbines

Stop wasting up to 50% of your power energizing the

coil of standard brush type alternators. Get a real PMA!

Permanent magnet alternators are by no means standard "Automotive" alternators containing brushes and electro-magnetic coils. A PMA does not waste power by having to continuously create an energy intensive magnetic field.

We sell only

highly efficient - long lasting

true permanent magnet alternators with Neodymium Magnets!

#PC series coils

with

Power-Core

rotor core PMA Technology!

Our "

Power-Core

" PMA rotor is

studded

with 14 powerful magnetic power points - Arranged in a Superbly balanced and perfectly phase biassing configuration. This new design feature offers high power with no appreciable cogging once at running speed.

All magnets are all slotted into multi-layered steel plates for maximizing and sharing the rear field forces boosting the overall core power.

When ordinary stator coils are hyper magnetically saturated with the

Power-Core

s

powerful magnetic field, power outputs are almost tripled over older mono core designs!

"The PC series PMA' are the most versatile PMA's we have ever built"

LOTS OF LOW END POWER GENERATION ABILITY!!!!

Perfect for building simple, inexpensive and dependable wind turbines.

A put-up and forget design! Expect decades of dependable service life.

All weather rated.

Rain, ice and weather proof electronics.

17MM hardened shaft.

Heavy Duty coils and diodes.

Light weight aluminum body.

Bearings rated for 115,000 hours +

D.C. output. Includes built in rectifier.

Warrant

y - 90 days parts and labor.

Powerful

Neodymium magnets in rotor.

#PC Series PMA's are our very powerful!

#PC1224AC -

(Used for Engine or Hydro powered battery charging)

Includes FREE pulley and cooling fan !!

Bi-rotational. Makes power when turned in either direction

.

18 hp depending on voltage demand and have a high voltage application.

Pulley and fan comes with all PC1224AC models !

(Smaller pulley sizes will slip on this ultra powerful model)

PC series PMA's weigh 11 LBS. - Size 8" X 7" X 7"

WARNING; High voltage PMA's and battery banks can cause lethal electric shock!

PLEASE NOTE: Our model numbers have nothing to do with voltages, they are just model numbers

GET FREE HOT WATER WHEN YOU USE WATER COOLED ENGINES

PMA Testimonials

I don't know if you remember me about 2 years ago I was asking you questions about your PMA's. They are great, attached is a photo of my engine setup that has over 5000 hours on them. I've just completed a 48 volt system and now am looking to finding out something about your HT48. At what wind speed does it start producing 48 volt power - even 10 watts? I'm thinking of putting two in series, isolating the ground or case in order to get them to produce something at a low wind speed.

Thanks

Bill Miller

W

ARNING!! Make sure you connect a PMA to the correct battery polarity. Positive PMA to positive battery terminal and negative PMA to negative battery terminal. IF you reverse the connections you will burn out your PMA as the power rushes past the blocking diodes and melts your coils!!!

HEAT WARNINGS:

Keeping your PMA's cooled, fused and under reasonable loads is the operators full responsibility. Monitor your PMA for excessive heating in all experimental machinery! Maximum PMA's operating temperature is 350 F. for 100% duty cycle. No

warranties

on ANY burned out PMA's! They are sold in good working condition and you have to keep them cool and never over loaded regarding amperage draw.

A PMA RUNNING SLOW WHILE DRAWING A FULL AMP LOAD IS A DEAD PMA!

Here is guide to help you choose the right PMA and keep it cool via the correct RPM V. AMPS coefficient

These figures must then be matched to the power curves. This total calculation must

be done

correctly or you may find yourself burning up a few PMA's as part of your learning curve.

(Expensive lessons for the inexperienced!!!!!!!!)

This advice is ONLY a guide line and is not a guarantee of cool operation since your amp load can still be to extreme for proper cooling. Don't pull more amperage than the PMA can handle. If you burn one up you own it!!! No warranties on burned up PMA's!!! All sales Final. If you are an amateur and do not understand electrical windings and how much heat they can take please don't buy one of our PMA's. If you are experienced watch for over heating and be careful. These PMA's really pack LOTS of POWER in a small package! Small power to size ratios always means

High Performance so

be careful

and use a fuse!

TECH NOTES:

Taking apart a PMA the right way.

1. Remove the 4 housing bolts and pull the front housing off OVER the shaft. Never pull the rear housing off first!!!!

If it is jammed or rusted use some WD-40 on the shaft and alternately tap the mounting wings with a hammer while applying pressure to the shaft with your thumb so that the stator and it's delicate wiring harness is kept in place. NOTE: If the shaft is QCored-up badly you may have to sand the shaft down to it's original 17mm size to get the front housing off.

2. Now grab the exposed rotor core shaft and pull it out WHILE holding down the stator ring with your index

finger and thumb. This will take LOTS of strength!!!!! If you fail to hold the stator in place the core and stator

will be extracted together and the wires will be torn off of the stator and this is unrepairable! This is a tricky maneuver and usually takes some experience and lots of muQCle!!!!!!!

3. Once the rotor core has been successfully extracted the rectifier connections are exposed and you may now unfasten the three wire nuts to safely remove the stator coil. (To reassemble simply reverse procedure)

Warranties will be void on any PMA that is opened by a customer.

Any PMA experimentation and examination is at your own risk.

CLICK DRAWING TO ENLARGE

negative ground